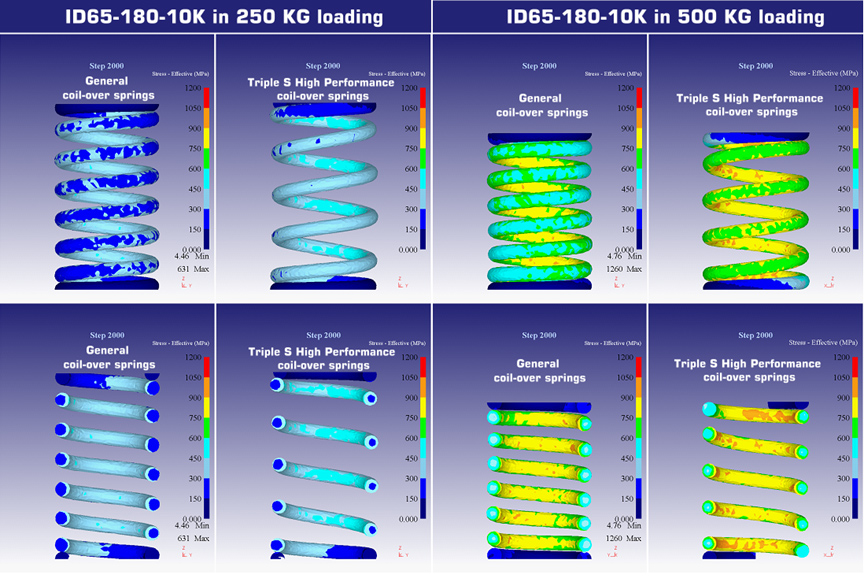

Test 1:3D Finite Element Analysis

Results:

-

What's different if we have loaded 250kg & 500kg to compare the 180-10K coil-over springs. It shows that Triple S have the more stroke to use and not easy to contact.

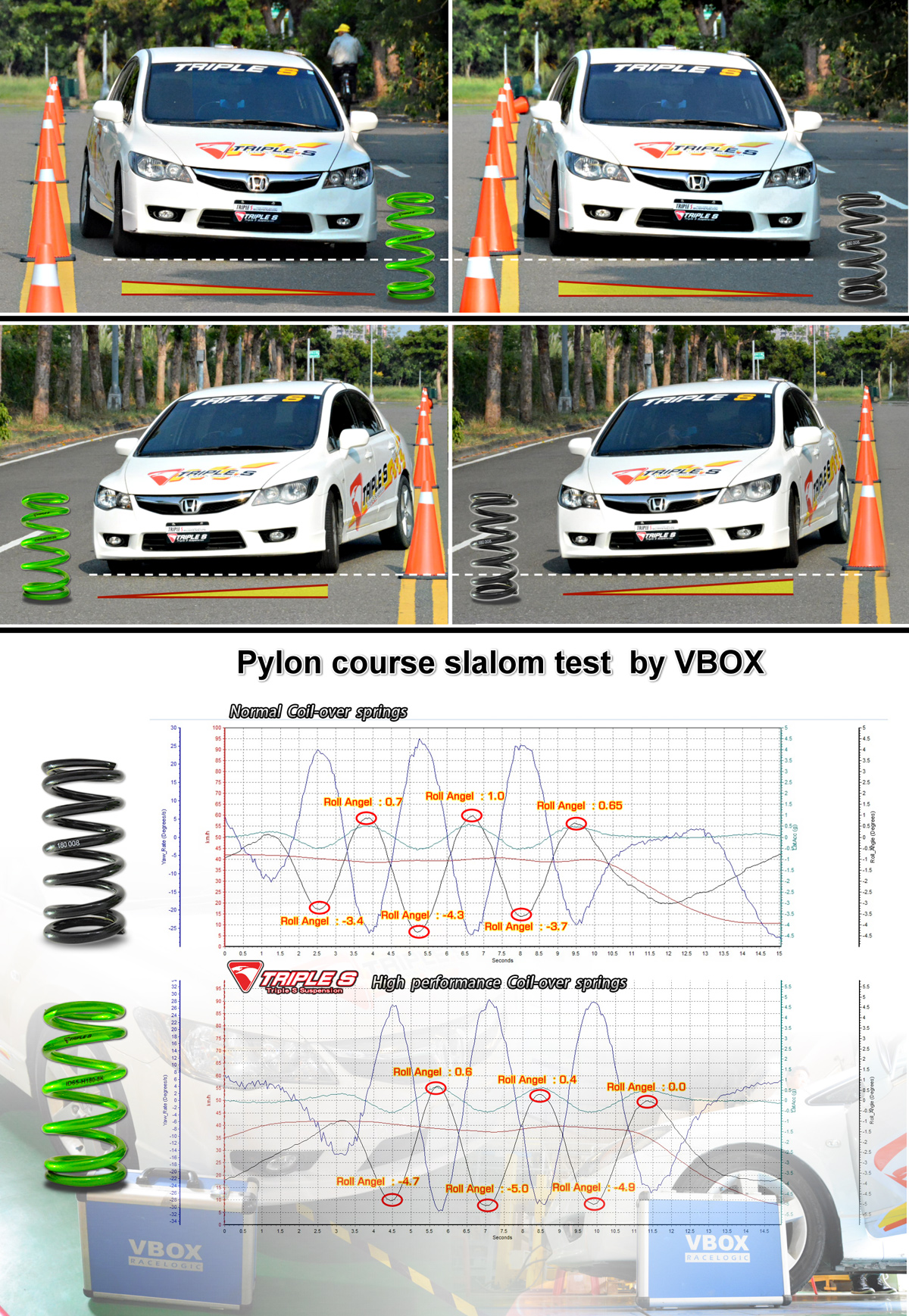

Test 4:Pylon course slalom test

Results:

-

Although the visual difference is limited. But the roll angle has been effectively reduced according to VBOX data. It proved that the Triple S high-performance spring can indeed suppress the roll angle.

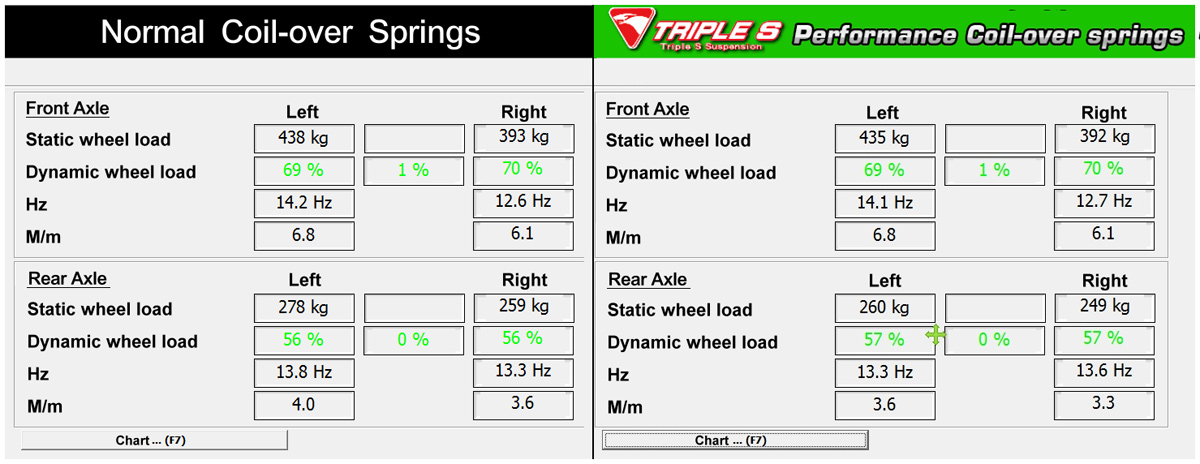

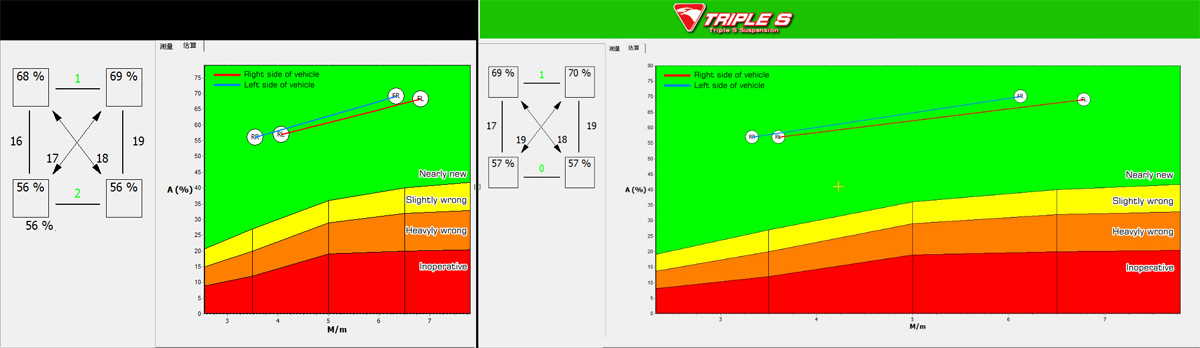

Test 5:SAXON Suspension test

Results:

-

The weight of the car is slightly reduced when it is in the static state due to the high stress of the spring. In addition, it is increased by 1% under the dynamic load. It shows that the Triple S high performance spring can indeed Increase the dynamic performance.

-

It shows the difference between the four rounds had narrowed to prove Triple S high-performance springs not only add the dynamic performance of the car but also made the four rounds more average.

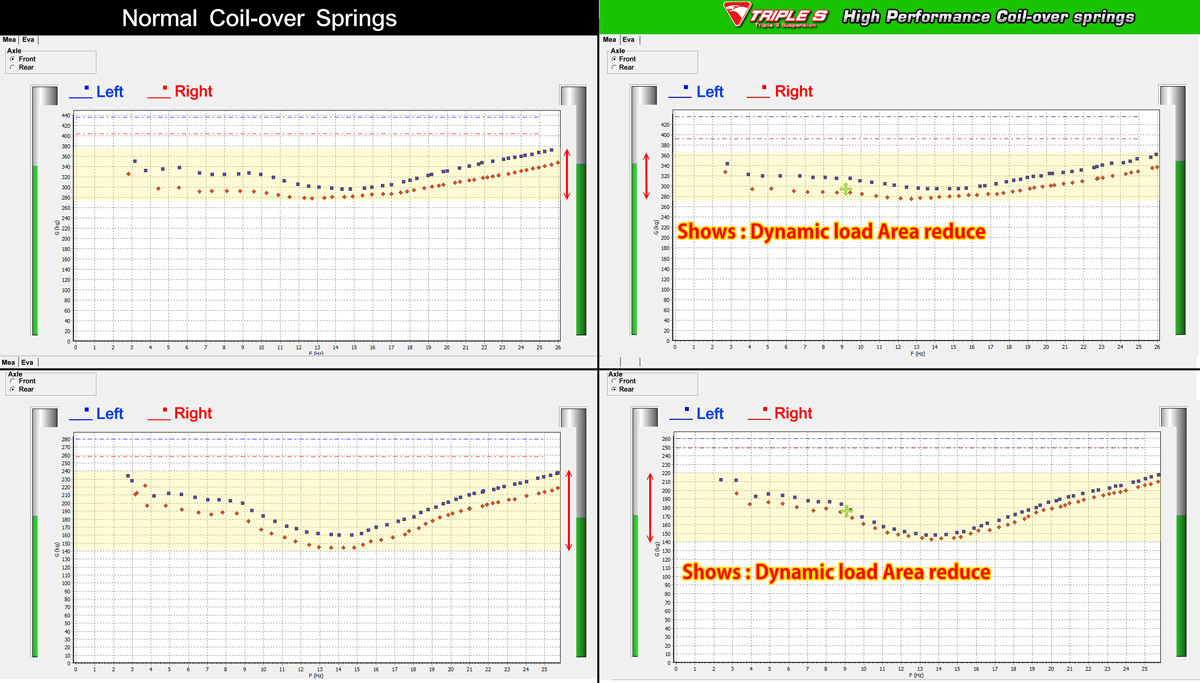

We can clearly see that the curves of the left and right shock absorbers of the 4 rounds under dynamic load are closer. Moreover, the starting point of the weight before and after the reduction is reduced, because the dynamic load of the high-performance spring is increased, so that the load of the suspension system can be reduced.

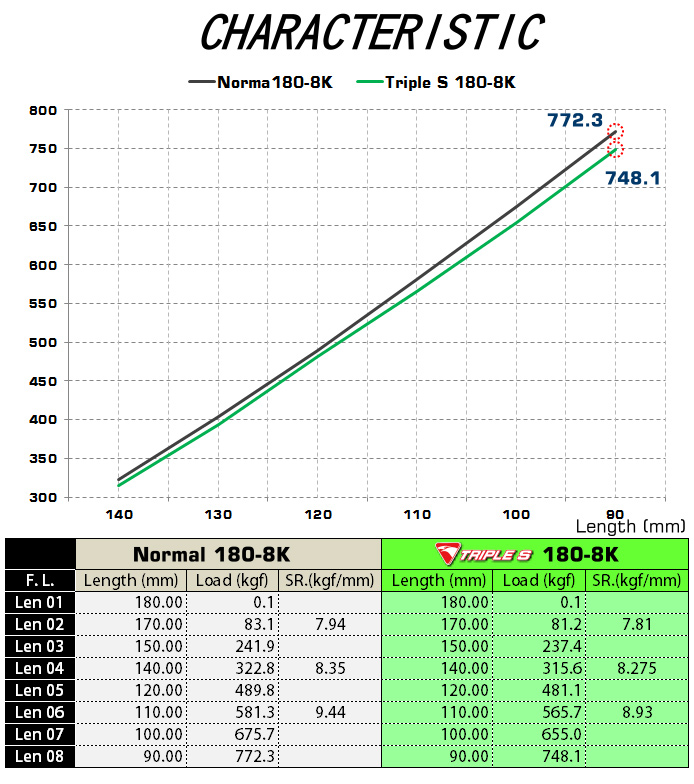

Test 6: Half stroke test

Results:

We tested with a 180-8K spring and made a curve for each degree of measuring point. We can see that the Triple S high-performance spring can achieve the same stroke with less load due to high stress characteristics. And the more the stroke is used, the more obvious, that indicates Triple S high-performance spring is indeed superior to the general spring due to its high stress characteristics, using less load.

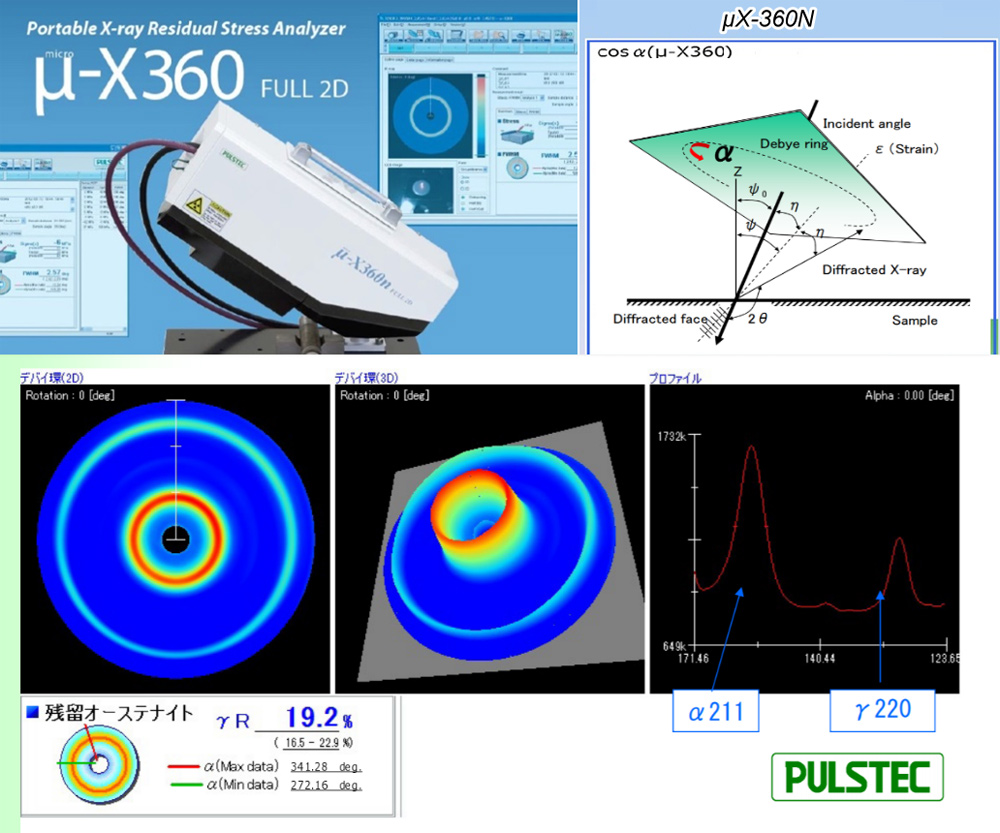

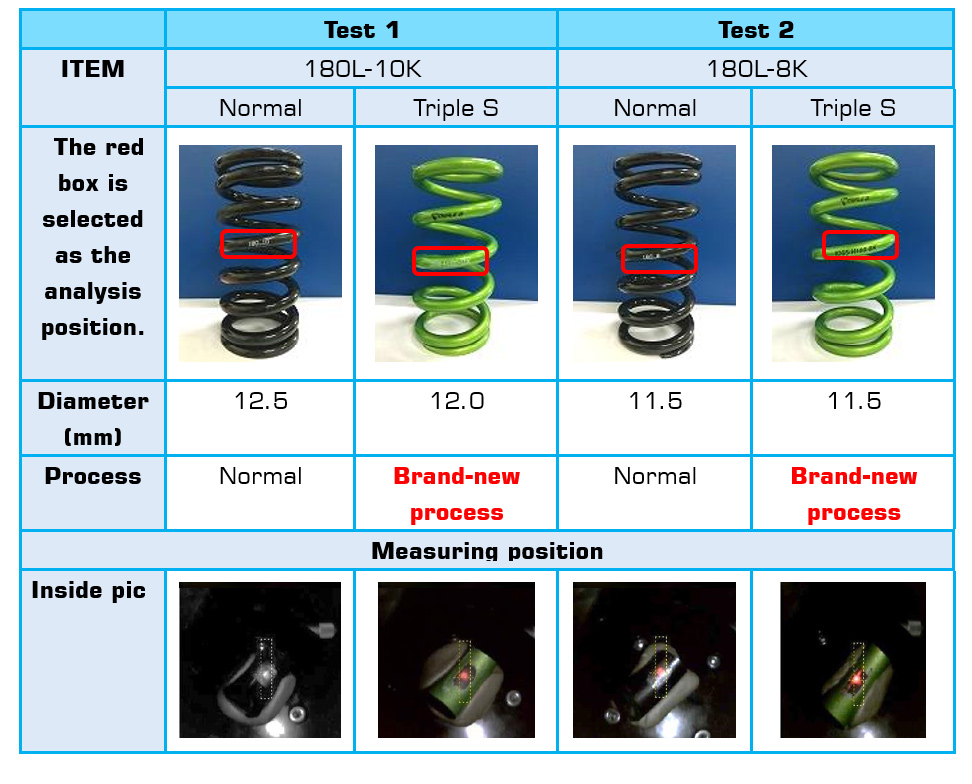

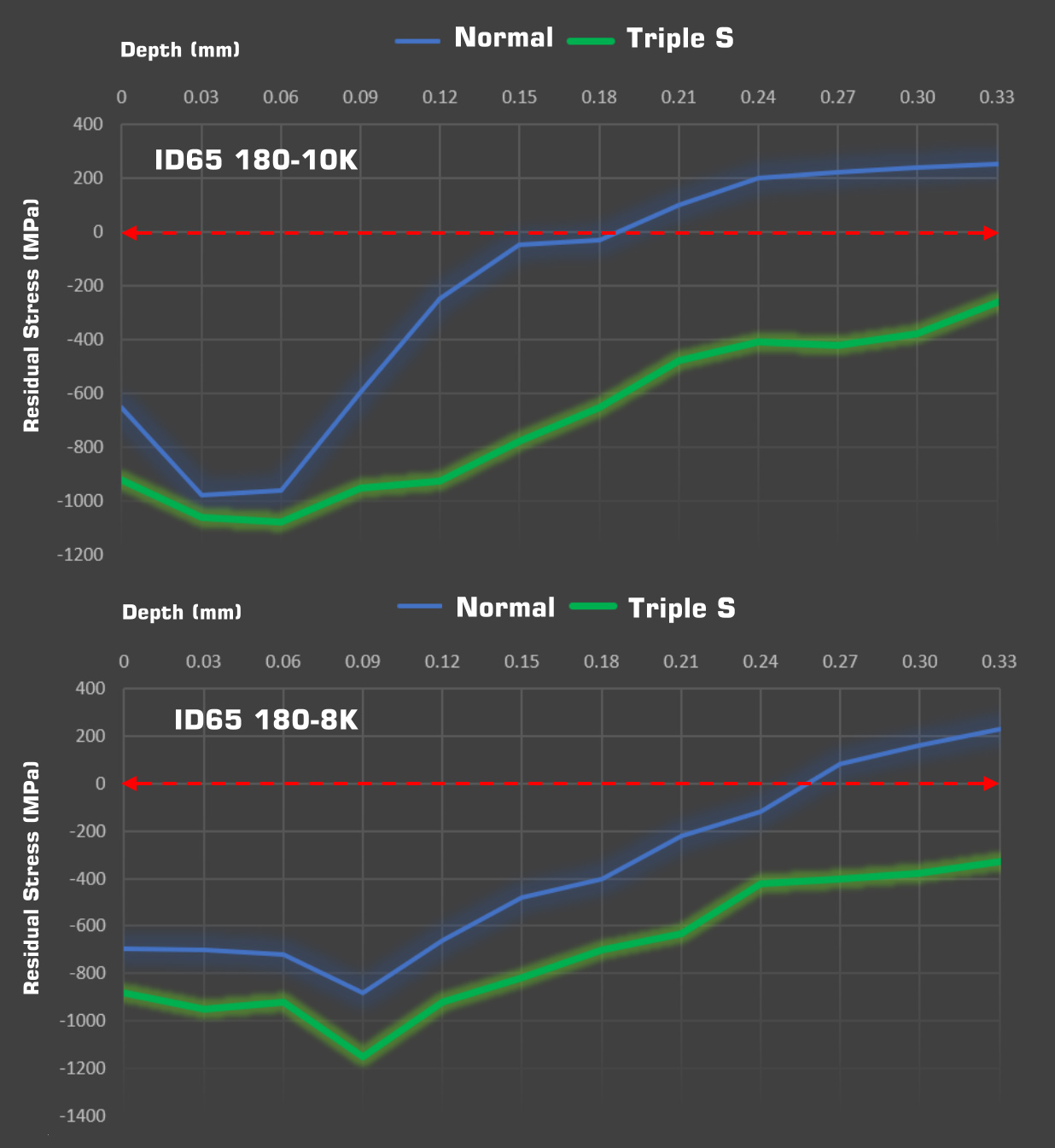

Test 7:Residual Stress test

You need to know before Test

- The stress defining a negative value (-) is the compressive stress, and the stress of the positive value (+) is the tensile stress. Stress can be multiplied and counteract.

- The greater the tensile stress, the more the spring defects are generated, so the tensile stress should be reduced as much as possible.

- Residual stress can be seen as the force resident in the spring. The spring residual compressive stress can be given through a professional process.

- When an external force is applied to the spring, the external force is converted into stress (both tensile stress and compressive stress). The tensile stress and the residual compressive stress counteract each other. The remaining stress causes the spring to deform.

Results:

- Triple S springs has smaller diameter, less coils and 20% lighter than normal springs.

- Triple S springs have the more negative residual stress than the normal spring, which can resist the tensile stress generated when the spring be used.

- Triple S springs’s negative residual stress is more deeply distributed in the spring wire than the the general springs, which can have more space to resist the tensile stress, so Triple S will have better spring life than the normal spring under the same conditions of use.